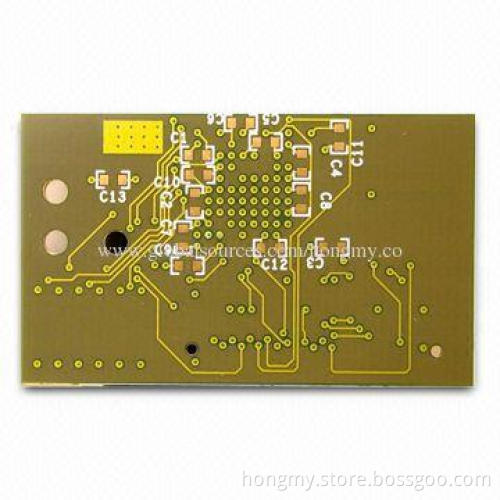

High-quality HASL Double-sided PCB with 3 to 8 Working Days Lead-time, Made of FR-4 Material

- Payment Type:

- T/T, L/C, Western Union, PayPal

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Payment Type: | T/T, L/C, Western Union, PayPal |

|---|

Product Description

Product Description

- Materials: FR4, aluminum base, Rogers, Taconic

- Layers: 1 to 16

- Copper thickness: 1oz

- Minimum line width: 0.2mm

- Minimum line spacing: 0.2mm

- Finishing board thickness: 0.2 to 3.2mm (8 to 126 mils)

- External copper thickness: 35 to 210um

- Internal copper thickness: 17 to 140um

- Copper plating hole: 18 to 40um

- Minimum trace width and line spacing: 0.075mm/0.1mm (3-mil/4-mil)

- Minimum hole dimensions (CNC): 0.20mm (8 mils)

- Minimum hole dimensions (punching): 0.9mm (35 mils)

- Maximum panel dimensions: 610 x 508mm

- Hole position tolerance (CNC): ±0.075mm

- With UL and RoHS marks

- Lead-time: 3 to 8 working days

- Hole dimensions tolerance (CNC):

- PTH: ±0.075mm

- NPTH: ±0.05mm

- Outline tolerance:

- CNC: ±0.125mm

- Punching: ±0.15mm

- Warp and twist: 0.70%

- Minimum solder mask bridge: 0.0635mm

- Distance between line to board edge outline: 0.25mm

- V-cut: 0.40mm

- Impedance control tolerance: ±10%

- Test voltage: 10 to 300V

- Solder mask colors: green, yellow, red, white, blue, matte green, matte black and more

- Surface treatment: HASL, immersion silver/gold, gold plating, gold finger

- PTH: ±0.075mm

- NPTH: ±0.05mm

- CNC: ±0.125mm

- Punching: ±0.15mm

Related Keywords

Related Keywords

You May Also Like

You May Also Like