Modular Units Heated Desiccant Air Dryer (2% purge air, -40C PDP, 29.5m3/min)

- Payment Type:

- L/C, T/T

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Shenzhen China |

|---|---|

| Payment Type: | L/C, T/T |

Product Description

Product Description

BITEMAN Modular units heated desiccant air dryer

Unique features

-Less than 2% purge air with only 0.4kw to 4.4kw power consumption,no auxiliary motor

-Pressure and inlet temperature is digital readout on screen,purge air gauge allows manually control regeneration air according to the wanted pressure dew point

-Small desiccan chambers' group,each chamber unit is independent and detachable

-Replace with factory filled desiccant chamber ,ease of maintenance and constant pressure dew point -40C (-40F) is ensured

-The lowest operation cost,user could recoup dryer investment in three years by saving huge air and electricity

-1/3 size to traditional dryer

-The shortest downtime

-Using Molecular sieve as desiccant

Details of advantages

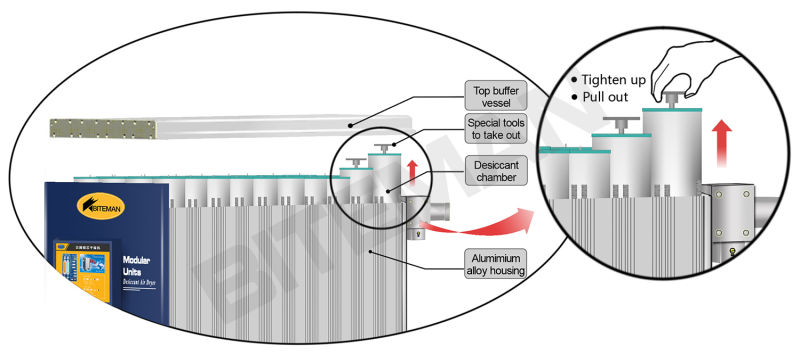

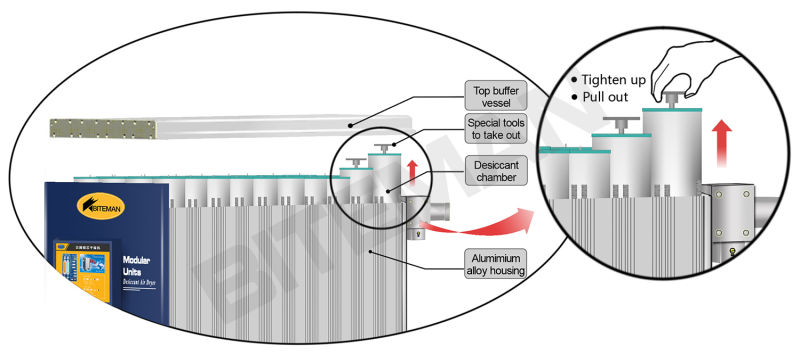

Innovative structure with patents,employs small desiccant chamber unit

1.Air flow equally and evenly pass through each desiccant chamber

2.Avoid channelling effect which more likely happens in traditional desiccant dryer

3.Small chamber allow no mandatory annul inspection

4.Molecular sieve capability is much better than Alumina and silicon desiccant in traditional dryer

5.PLC controller ,Full function touch panel control

Structure and operation

Biteman dryer have two groups of desiccant chambers,A and B ,according to flow rate,A and B shift between adsorption and regeneration

Ease of replacement of desiccant chambers,it can't be more simpler comparing to exchange of desiccant,only one wrench it is done.Further more,needn't worry the desiccant density after refilling because it is filled in our factory to keep constant and stable pressure dew point,just like new dryer from factory

Unique features

-Less than 2% purge air with only 0.4kw to 4.4kw power consumption,no auxiliary motor

-Pressure and inlet temperature is digital readout on screen,purge air gauge allows manually control regeneration air according to the wanted pressure dew point

-Small desiccan chambers' group,each chamber unit is independent and detachable

-Replace with factory filled desiccant chamber ,ease of maintenance and constant pressure dew point -40C (-40F) is ensured

-The lowest operation cost,user could recoup dryer investment in three years by saving huge air and electricity

-1/3 size to traditional dryer

-The shortest downtime

-Using Molecular sieve as desiccant

Details of advantages

Innovative structure with patents,employs small desiccant chamber unit

1.Air flow equally and evenly pass through each desiccant chamber

2.Avoid channelling effect which more likely happens in traditional desiccant dryer

3.Small chamber allow no mandatory annul inspection

4.Molecular sieve capability is much better than Alumina and silicon desiccant in traditional dryer

5.PLC controller ,Full function touch panel control

Structure and operation

Biteman dryer have two groups of desiccant chambers,A and B ,according to flow rate,A and B shift between adsorption and regeneration

Ease of replacement of desiccant chambers,it can't be more simpler comparing to exchange of desiccant,only one wrench it is done.Further more,needn't worry the desiccant density after refilling because it is filled in our factory to keep constant and stable pressure dew point,just like new dryer from factory

Related Keywords

Related Keywords

You May Also Like

You May Also Like