Desiccant Masterbatch for Moisture Absorber (DM200)

- Payment Type:

- L/C, T/T, D/P

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Huizhou, China |

|---|---|

| Payment Type: | L/C, T/T, D/P |

Product Description

Product Description

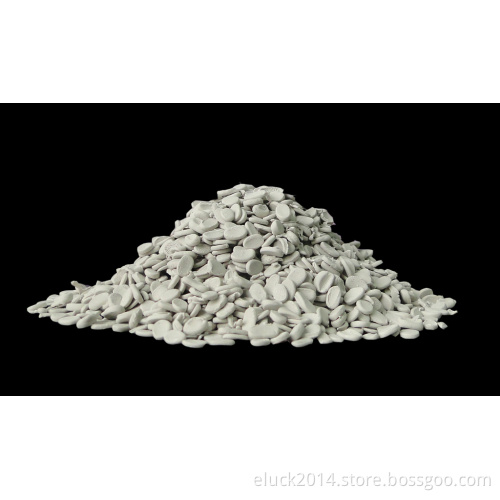

Plastic Desiccant Masterbatch (Moisture Absorber) --DM200

Recycled Polyethylene(PE) or Recycled Polypropylene(PP)often contains some moisture,if not eliminated, the moisture will produce drain marks or bubbles on the surface of the final products while processing, besides quality affected, the moisture even cause impossibility of processing.

Plastic desiccant masterbatch DM200 is a new type of functional masterbatch developed to eliminate the moisture of recycled PE and recycled PP. With adding a small rate of DM200,by mixing with material,it can absorb the moisture during production process and save drying process. DM200 is environment-friendly and can save production time, energy and cost.

Application: DM200 are widely used in recycled PE,PP and wet material. It can be used in the production of injection, blowing film.

Performance Index

Item Index Method of Testing

Carrier PE /

Additive Desiccant /

MFI (g/10min) 7.50 GB/T3682-2000 D Method

Density (g/cm3) 1.70 GB/T1033-86 B method

Color White granule Visions Judgement

Content:

Oxide Calcium - 75%, PE material-18.5%, PE wax-6.5%

Appearance:

Dim2.5MM *Thickness 1.0MM round granule, Dark grey.

Characteristic :

1. Can reduce or prevent the drain mark and bubbles by absorbing moisture

2. Can absorb the moisture equivalent to 20% of the weight of desiccant masterbatch

3. Not affect to production technology and process.

4. SGS certificate

Usage :

1. Check the condition of inner packing and forbid using if breakage.

2. Use over within 16 hours after opening the packing.

3. Adding rate:1%~3%

4. Mixed with the raw material.

5. Do not heat with recycle material

Packing and storage

1. 5kg per vacuum PE bag, 5 bags per carton.

2. Handle carefully to avoid package damaged.

3. Store in ventilated, dry, and cool place to keep out of sun exposure and rain.

4. Recommended storage life: Up to 6 months provided it is stored as directed.

Related Keywords

Related Keywords