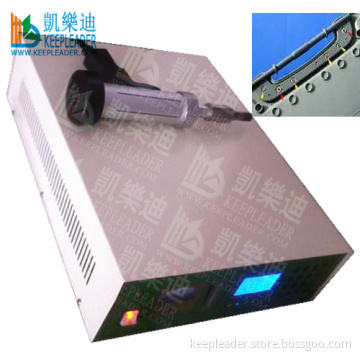

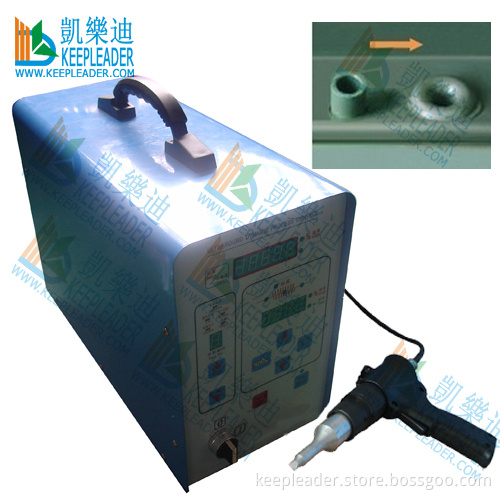

Ultrasonic Plastic Spot Welder of Handheld Style, 500W, 28kHz

- Payment Type:

- L/C, T/T, D/P

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Sz, Cn, Ultrasonic Plastic Spot Welder |

|---|---|

| Payment Type: | L/C, T/T, D/P |

Product Description

Product Description

KEEPLEADER INTRODUCTION

HK KEEPLEADER CO., LTD is a hi-tech joint venture, Located in Beautiful HongKong, was founded in 2009, now it has Sales office in Shenzhen, Shanghai and Beijing City, which is organized by SHENZHEN KEEPLEADER CO., LTD to expand international Service and cooperation, we call it Marketing and Service Center, has recruited many well educated and qualified Engineers and Sales representatives, KEEPLEADER has its shareholding factory, is Mainly manufacturing Ultrasonic Cleaning Machine, Ultrasonic Welding Machine, High Frequency Welding Machine and peripheral machines concerning Ultrasonic and High Frequency Technology, KEEPLEADR Adopted Constructive and win-win nature of market model, Sales and Production is separated, by Which the customers to Maximize their protection of interest, in order to provide comprehensive ranges of solution, Basing on our Manufacture, HK KEEPLEADER has established Strategic partnership with many top-list factories in Shenzhen City and Dongguan City of Guangdong providing, Jinhua city and Ruian city of Zhejiang province, Wuxi, Changzhou city of Jiangsu province, The market Center has been dedicated to optimization and integration of developing, producing, marketing, service and application technology of ultrasonic and high frequency technology, and providing quality products and best solution for users, also has recruited many well educated and qualified engineers to keep our machine be fresh design, quality-improved, customized and easy-to-operate and maintenance, also many of experienced, down-to- earth sales representatives to provide good after service

MAINLY APPLICATION

01: Welding: With ultrasound ultrahigh frequency vibration welding head in moderate pressure, make two pieces of plastic joint surface produce friction heat and instant melting joint, the welding strength can be comparable with the ontology, adopting appropriate workpiece and reasonable interface design, can achieve watertight and airtight, and exempt from the AIDS the inconvenience, achieve high efficiency and clean welding.

02: Rivet welding: Ultrasound ultrahigh frequency vibration welding head, pressure plastic product outstanding the tip of a branch, make its instant heating melting become rivet shape, made of different materials material mechanical riveting together.

03: Heeling in: Through the welding head of the ministry and the appropriate pressure, moment will metal parts (such as nut, screw, etc. ) Pile in reserve into plastic hole, fixed in a certain depth, after the completion of whether pulling force, torque are comparable in the mould of traditional molding intensity, can be exempt from injection mold damage and injection of the shortcomings of slow.

04: Forming: This method and riveting method similar cavernous welding head pressure in plastic product case and welding hair favorable balance of trade sonic ultra-high frequency vibration after plastic melt forming and coated metal objects in its fixed, and smooth appearance beautiful, this method used in electronics, horn of the fixed forming, and cosmetics kind of lens fixed, etc.

05: Spot welding: Two piece of plastic equinoctial welding without preliminary design welding line, achieve welding purpose; Contrast larger workpiece, is not easy to design welding line of the workpiece equinoctial welding, and to achieve welding effect, but at the same time spot welding more.

06: Cutting seal: Using ultrasound instant hair vibration principle of chemical fiber fabrics by cutting, its advantages incision bright and clean and no crack, and not drawing.

HK KEEPLEADER CO., LTD is a hi-tech joint venture, Located in Beautiful HongKong, was founded in 2009, now it has Sales office in Shenzhen, Shanghai and Beijing City, which is organized by SHENZHEN KEEPLEADER CO., LTD to expand international Service and cooperation, we call it Marketing and Service Center, has recruited many well educated and qualified Engineers and Sales representatives, KEEPLEADER has its shareholding factory, is Mainly manufacturing Ultrasonic Cleaning Machine, Ultrasonic Welding Machine, High Frequency Welding Machine and peripheral machines concerning Ultrasonic and High Frequency Technology, KEEPLEADR Adopted Constructive and win-win nature of market model, Sales and Production is separated, by Which the customers to Maximize their protection of interest, in order to provide comprehensive ranges of solution, Basing on our Manufacture, HK KEEPLEADER has established Strategic partnership with many top-list factories in Shenzhen City and Dongguan City of Guangdong providing, Jinhua city and Ruian city of Zhejiang province, Wuxi, Changzhou city of Jiangsu province, The market Center has been dedicated to optimization and integration of developing, producing, marketing, service and application technology of ultrasonic and high frequency technology, and providing quality products and best solution for users, also has recruited many well educated and qualified engineers to keep our machine be fresh design, quality-improved, customized and easy-to-operate and maintenance, also many of experienced, down-to- earth sales representatives to provide good after service

MAINLY APPLICATION

01: Welding: With ultrasound ultrahigh frequency vibration welding head in moderate pressure, make two pieces of plastic joint surface produce friction heat and instant melting joint, the welding strength can be comparable with the ontology, adopting appropriate workpiece and reasonable interface design, can achieve watertight and airtight, and exempt from the AIDS the inconvenience, achieve high efficiency and clean welding.

02: Rivet welding: Ultrasound ultrahigh frequency vibration welding head, pressure plastic product outstanding the tip of a branch, make its instant heating melting become rivet shape, made of different materials material mechanical riveting together.

03: Heeling in: Through the welding head of the ministry and the appropriate pressure, moment will metal parts (such as nut, screw, etc. ) Pile in reserve into plastic hole, fixed in a certain depth, after the completion of whether pulling force, torque are comparable in the mould of traditional molding intensity, can be exempt from injection mold damage and injection of the shortcomings of slow.

04: Forming: This method and riveting method similar cavernous welding head pressure in plastic product case and welding hair favorable balance of trade sonic ultra-high frequency vibration after plastic melt forming and coated metal objects in its fixed, and smooth appearance beautiful, this method used in electronics, horn of the fixed forming, and cosmetics kind of lens fixed, etc.

05: Spot welding: Two piece of plastic equinoctial welding without preliminary design welding line, achieve welding purpose; Contrast larger workpiece, is not easy to design welding line of the workpiece equinoctial welding, and to achieve welding effect, but at the same time spot welding more.

06: Cutting seal: Using ultrasound instant hair vibration principle of chemical fiber fabrics by cutting, its advantages incision bright and clean and no crack, and not drawing.

Related Keywords

Related Keywords

You May Also Like

You May Also Like