Automatic 100-2000L Beer Brewery Equipment

- Payment Type:

- L/C, T/T, Western Union

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Payment Type: | L/C, T/T, Western Union |

Automatic 100-2000L Beer Brewery Equipment

Application:

This beer brewery equipment which is not only suitable for the small scale beer factory and also

suitable for the draft beer brewing of tourist resorts, hotels, pubs.

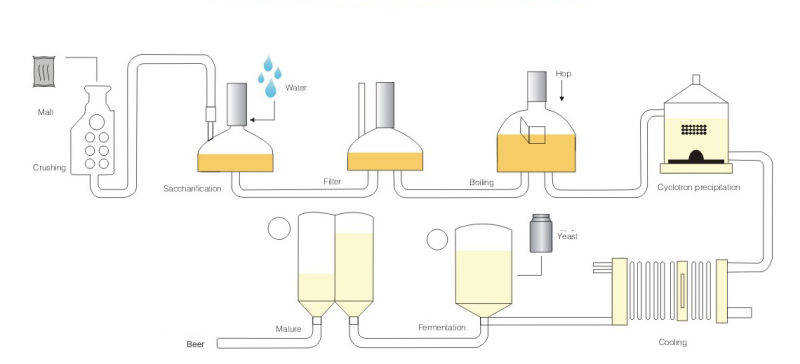

The draught beer equipment include malt crushing system, brewery house, fermentation system,

bright beer system, cooling system, electric control system, CIP system, water system and the connection pipes etc.

Brewhouse

Brewhouse includes mash, boiling, lauter and whirlpool four function.

Includes mash/kettle tun, lauter/whirlpool tun, wort pump, plate cooler, wort Oxygenator, electric control system,

platform, pipes and fittings. It can be two vessel, three vessel, four vessel or five vessel which is customized

according to process.

Heating method: electric heating, steam heating, gas heating.

Capacity: 100L, 300L, 500L, 1000L, 2000L

Fermentation System

The fermentation tank includes pre-fermentation and fermentation, pre-fermentation tank is called open fermentation tank also. Fermentation tank is conical fermentation tank.

Dimple Jacket Conical Fermentation Tank

The conical bottom cylinder fermentation tank is the major equipment of brewery fermentation system

which is suitable for the small scale beer manufacturer, especially for draft beer brewing of tourist resorts,

hotels, pubs.

The cold wort is delivered to the fermentation tank via the inlet of the tank after filtration and inoculated

with yeast for fermentation.

The heat generated during the fermentation is taken away through refrigerant in the jacket which enables

the fermentative process to be carried on stably. The wort temperature, yeast quantity, fermentation time

are subject to the fermentation process requirement.

The working temperature inside the tank is 2~15ºC, working pressure on the top of the tank is 0.1MPa.

The sediment yeast is discharged first and then the fermentation liquor when the wort fermenting liquor

reach the technological requirement. Clean the tanks completely for next process after empty the

fermenting liquor

It uses ethylene glycol as refrigerant to make heat exchange in the dimple jacket.

Bright Beer System

Bright beer tank has elliptical bottom or cone bottom. It is the main equipment before beer packing.

It is used to store the beer after filtration, The working temperature inside the tank is 2~4ºC,

working pressure on the top of the tank is 0.2~0.3MPa. Clean the tanks completely for next process

after empty the tank.

It uses ethylene glycol as refrigerant to make heat exchange in the dimple jacket.

Anymore information, pls feel free to contact us, we will reply you with 24 hours.

Related Keywords