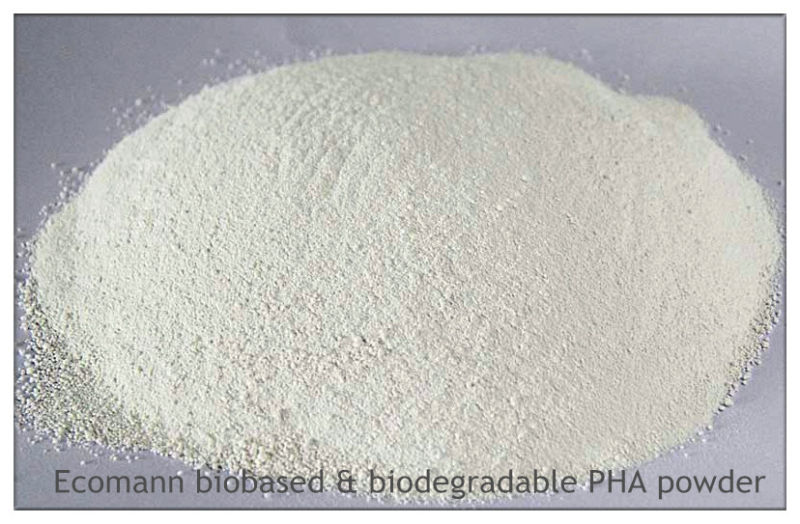

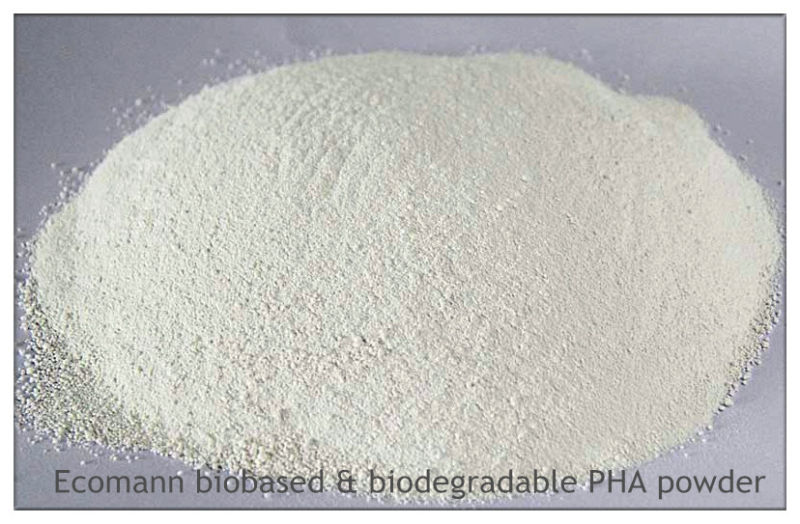

Biobased Polyhydroxyalkanoates (PHA) Biopolymers Powder

- Payment Type:

- L/C, T/T

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | P. R. China |

|---|---|

| Payment Type: | L/C, T/T |

Product Description

Product Description

Innovation:

Ecomann PHA (polyhydroxyalkanoates) biopolymers are liner polyester produced in nature by bacterial fermentation of sugar or lipids. They are produce by the bacteria to carbon and energy.

More than 150 different monomers can be combined within this family to give materials with extremely different properties. After the bacteria have made the resin they are washed out leaving a power that can be processed either directly into plastic products or shaped into pellets for further processing.

They can be either thermoplastic or elastomeric materials, with melting points ranging from 41 to 180 celcius.

The mechanical and biocompatibility of PHA can also be changed by blending, modifying the surface or combining PHA with other polymers, enzymes and inorganic materials, making it possible for a wide range of applications.

Properties:

Properties:

a. Molecular weight: 500, 000— 800, 000

b. Glass transition temperature: -20 degree centigrade to 0 degree centigrade

c. Melting point: 80 degree centigrade to 160 degree centigrade

d. Crystallinity: Lower than 20%

e. Elongation at break: 5% to 1000%

f. Isolation of air and water: Similar to PET

g. Printing properties: Similar to PET

h. Very good anti-UV properties

i. Stable in water, but biodegradable in sea and soil

j. No secondary pollution to the environment

Application:

1) serve as modifiers for other biopolymers like PLA, to imporve its ductility and flexibility

2) serve as raw material to make absorbable surgical sugure sutures, absorbable screw

Ecomann PHA (polyhydroxyalkanoates) biopolymers are liner polyester produced in nature by bacterial fermentation of sugar or lipids. They are produce by the bacteria to carbon and energy.

More than 150 different monomers can be combined within this family to give materials with extremely different properties. After the bacteria have made the resin they are washed out leaving a power that can be processed either directly into plastic products or shaped into pellets for further processing.

They can be either thermoplastic or elastomeric materials, with melting points ranging from 41 to 180 celcius.

The mechanical and biocompatibility of PHA can also be changed by blending, modifying the surface or combining PHA with other polymers, enzymes and inorganic materials, making it possible for a wide range of applications.

Properties:

Properties:a. Molecular weight: 500, 000— 800, 000

b. Glass transition temperature: -20 degree centigrade to 0 degree centigrade

c. Melting point: 80 degree centigrade to 160 degree centigrade

d. Crystallinity: Lower than 20%

e. Elongation at break: 5% to 1000%

f. Isolation of air and water: Similar to PET

g. Printing properties: Similar to PET

h. Very good anti-UV properties

i. Stable in water, but biodegradable in sea and soil

j. No secondary pollution to the environment

Application:

1) serve as modifiers for other biopolymers like PLA, to imporve its ductility and flexibility

2) serve as raw material to make absorbable surgical sugure sutures, absorbable screw

Related Keywords

Related Keywords