Platinum-Catalysed (Addition Cure) Silicones

Your message must be between 20 to 2000 characters

Contact NowBasic Specification

| color | any |

|---|---|

| application | Platinum-Catalysed (Addition Cure) Silicones |

| hs code | 39100000 |

| appearance | liquid silicone |

| operation | injection |

| Eco-Friendly | Yes |

| Test Report | SGS |

Detail Description

Platinum-Catalysed (Addition Cure) Silicones

Platinum-Catalysed (Addition Cure) Silicones features: favorable hardness, light viscosity, good liquidity, low shrinkage.

Platinum-Catalysed (Addition Cure) Silicones applications

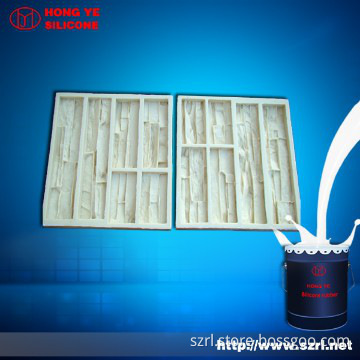

Platinum-Catalysed (Addition Cure) Silicones used in mold making field for manufacturing products made of materials including wax, low melt alloys/metals and urethane, epoxy or polyester resins, gypsum, plaster, cement, wax, unsaturated resin, epoxy resin, etc.

Platinum-Catalysed (Addition Cure) Silicones will reproduce the finest detail and are suitable for a variety of industrial and architecture related applications including making molds for reproducing prototypes, furniture, sculpture and architectural elements.

Platinum-Catalysed (Addition Cure) Silicones features

Platinum-Catalysed (Addition Cure) Silicones are two component materials which cure at room temperature (RTV) to flexible, high tear strength rubbers. Liquid Silicone and Curing Agent can be poured into models or can be made brushable by adding a thixotropic additive.

They are ideal for molds where easy release or high temperature resistance is required. Liquid Silicone and Curing Agent can be used for casting polyurethane, epoxy and polyester resins, waxes, all gypsum products and low temperature metals.

Package, Storage, Transportation and Notes of Platinum-Catalysed (Addition Cure) Silicones

1.Platinum-Catalysed (Addition Cure) Silicones are packed in 200 kg, 25kg per drum, and the curing agent/catalyst/hardener is packed in 1kg per plastic bottle. We offer 25kg packing with vacuumed packing

2.Platinum-Catalysed (Addition Cure) Silicones should be sealed and deposited in a shade, dry place to prevent rain, sunlight exposure.

3.The storage period of Platinum-Catalysed (Addition Cure) Silicones is 10 to 12 months. If the viscosity increases, stir the rubber uniformly before use, and property unchanged.

4.If the Platinum-Catalysed (Addition Cure) Silicones are used in the reproduction of glass, ceramic, resin, wood etc., or the surface painted, coat the surface of prototype with surfactant (such as detergent, shampoo or soapy water) uniformly, and perfuse or brush silicone rubber after water volatilized, which is easier for mould unloading.

5.The Platinum-Catalysed (Addition Cure) Silicones are non-dangerous goods, but please avoid skin and eyes contacting with the curing agent in processing. Once exposed, immediately wash with certain detergent and water. If splash into eyes, should wash with flowing water at least 15 minutes and consult a doctor.

Need any help on silicone rubber, please feel free to contact Ms Kitty:

Tel:86-755-89948294

Mob:86-15989267535

E-mail: hysh(at)szrl(dot)net

Skype:kity-467707861

You can also send me e-mail by scanning 2 Dimensional Bar Code below:

Additional Information

| Payment Terms | L/C, T/T |

|---|---|

| Minimum Order | 200kg |

| Lead Time / Delivery Time | 4 Day(s) |

| Sample Available | YES |

| Delivery Details | within three days after getting your payment |

| FOB Port | Shenzhen |

| Loading Info | Shenzhen port by sea |

| Packing Info | 20kg and 200kg per drum |

| Target Market(s) | North America, Oceania, Southeast Asia, Eastern Europe, Africa(except Middle East), Hong Kong/ Macao/ Taiwan, Latin America, Japan & Korea, Mainland China, Western & Southern Europe, Northern Europe, Central & Southern Asia, Middle East |

Related Keywords