like shinetsu addition cure moldmaking silicones for polyurethane mold

Your message must be between 20 to 2000 characters

Contact NowBasic Specification

| appearance | liquid material |

|---|---|

| application | Molds making silicone rubber for culture relics |

| validity | 1 year |

| type | addition |

| supply ability | 8 ton a day |

| Eco-Friendly | Yes |

| Test Report | SGS |

Detail Description

like shinetsu addition cure moldmaking silicones for polyurethane molds

Description

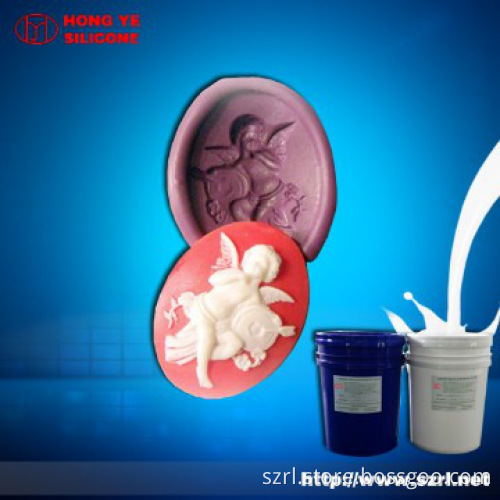

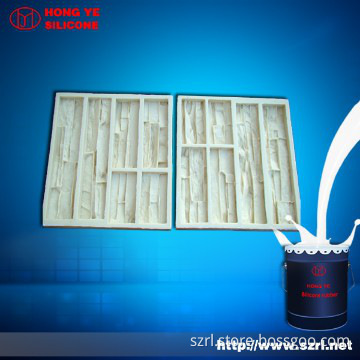

Our E640 addition cure moldmaking silicones is featured with almost nil shrinkage and perfect fluidity; Without releasing any by-product with low molecular weight, and it\'s cured fully from top to bottom, from the inside and outside simultaneously, so it will be deeply-cured. The E sereise addition cured silicone will not meet the problem of degradation or sticky molds because of the existence of by-product of small molecules under certain conditions, (such as closed, high temperature).it\'s very ideal material for moldmaking and casting, such as stone concrete molds, cement molds, statue molds, reproduction for crafts or toys, and so on. The cured mold can be reused for hundreds of times, without transformation and distortion. Its durability is so strong that it sells very well in the global markets.

Typical Applications

Our E640 addition cure moldmaking silicones can be used in not only the field of common RTV 2 part moldmaking silicone. As the vulcanizing reactions of addition cure silicone is fundamentally different from tin cure silicone’s, it has no problem of deep vulcanizing or reverse reaction, or other problem. Therefore, our addition cure silicone is particularly applicable for plaster silicone molds, cement product mold, other molds even with big size, and so on. It features with lower viscosity, high strength , good fluidity, so it can also be very suitable for the replication for the models with precision and complex pattern. From the following information, you will get a full view of its performance.

Characteristics

-Will not damageth e master

-Allows the moldert o meett hosec ritical deadlinesth at haven o room for error

-Provides multiple pulls per mold

-Offersv isible air managemendtu ringt he pour

-Offers extremely low shrinkage

-Has good resin resistance

Technical Parameters

Model |

Appearance |

Viscosity (cps) |

Hardness (A°) |

Tensile strength (Mpa) |

Tear strength (KN/m) |

Elongation (%) |

Mixing ratio (%) |

Operating time(H) |

Curing time(H) |

E-640 |

translucent |

30000±8000 |

42±2 |

≥4.0 |

≥7 |

≥200 |

2~3 |

0.5~1 |

2~5 |

Please note: the above data for this product in 25°C temperature, 55percent humidity conditions, for reference. The accurate data is measured by customers when using.)

Frequently asked questions:

Why is the silicon mold oily?

The molding silicone rubber itself doesn’t contain any oil, so it won’t be oily. If the mold is oily, it may be because you add the compound silicone oil( the compound of silicon oil and white oil). The white oil is not silicon oil but a kind of petrochemicals.

Twelve (12) months from date of shipment when stored at 24°C in original unopened packages.

PACKAGE

Packed in clean 25kg/pail, 200kg/pail.

Additional Information

| Payment Terms | L/C, T/T, Credit Card, Western Union |

|---|---|

| Minimum Order | 200kg |

| Lead Time / Delivery Time | 5 Day(s) |

| Sample Available | YES |

| Delivery Details | within 3 days after getting payment |

| FOB Port | Shenzhen |

| Loading Info | by ship or air |

| Packing Info | 25kg/drum and 200kg/drum |

| Target Market(s) | North America, Oceania, Southeast Asia, Eastern Europe, Africa(except Middle East), Hong Kong/ Macao/ Taiwan, Latin America, Japan & Korea, Mainland China, Western & Southern Europe, Northern Europe, Central & Southern Asia, Middle East |

Related Keywords